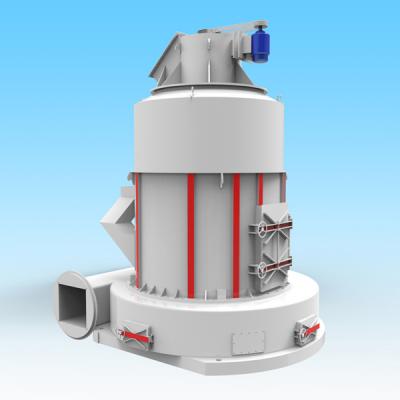

1. The grinding roll of the

roll mill crusher is equipped with replaceable wear-resistant lining board. The wear-resistant lining board is made of domestic advanced wear-resistant materials. It has the advantages of long service life, easy damage and convenient maintenance. Continuous service life can be more than one year. When the wear is serious, the cover can be replaced by removing it. Small maintenance and low cost are incomparable to any other type of crusher in China.

2. The roll mill crusher is equipped with safety protection device. When an accidental metal iron piece enters the crushing chamber, the protection device acts and the iron leakage equipment works normally.

3. The roll gap of abrasive roll body of roll mill crusher can be adjusted arbitrarily between 1 mm and 20 mm. After adjusting the roll gap according to the requirement of crushing particle size, the crushing particle size can be controlled reliably, and all of them are discharged from below the crushing cavity with ideal particle size.

4. The structure is simple and reasonable, the operation cost is low, the operation is stable, the efficiency is energy-saving, the crushing efficiency is high, and the discharging granularity is adjustable.

5. The

roll mill crusher is the working principle of low-speed and high-pressure roll-to-roll extrusion. The material falls vertically into the crushing chamber from the upper part of the crusher. Under the strong pressure produced between the two rollers, most of the material has become powdery, and a large number of cracks have been produced in the interior of the remaining small part of the granular material. In the further grinding process, the grinding energy consumption can be greatly reduced and the output can be increased.

6. Equipped with roll mill crusher in grinding system, the production capacity of grinding equipment can be fully developed. Generally, the output can be increased by 30%-40%, and the total energy consumption can be reduced by 20%-30%.

7. It has compact structure, light weight and small volume. For grinding systems with the same production capacity, the equipment of

roll mill crusher can significantly save investment.

8. It has simple structure, small occupancy space and convenient operation and maintenance.

9. Dust-proof board is installed in the interior, which has good sealing performance, avoids splashing of small crushed materials, less dust, low working noise, and greatly improves the working environment.

10. The abrasive roll weight is optimized again. There is no need to change the roll body of the mill for the whole life of the equipment, while the old roll-counter machine needs to be dismantled and overhauled for one year.

GUIKUANG is a professional expert grinding mill manufacturer from China. Welcome to visit our factory and we can make design for your project.

GK2500 Raymond Mill2017/11/28GK2500 Grinding Mill is designed by our technicians according to market development demand. This is a superlarge innovative type mill with optimized design.

GK2500 Raymond Mill2017/11/28GK2500 Grinding Mill is designed by our technicians according to market development demand. This is a superlarge innovative type mill with optimized design.