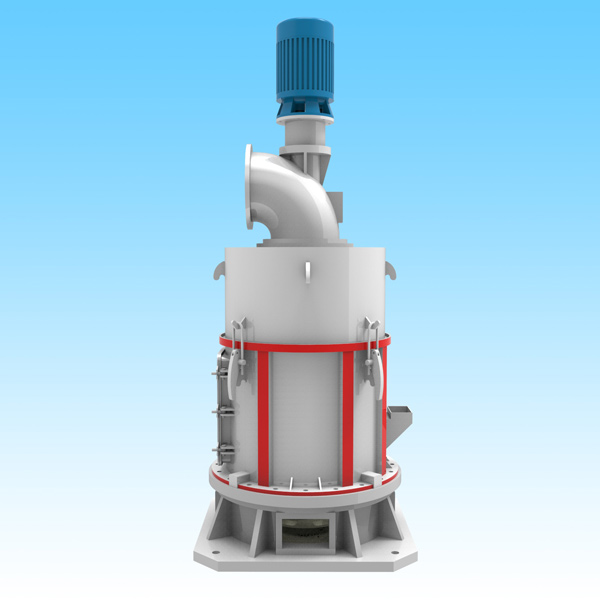

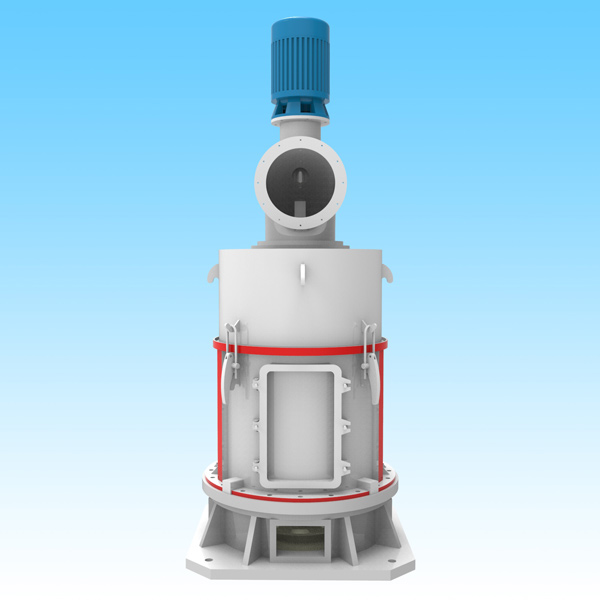

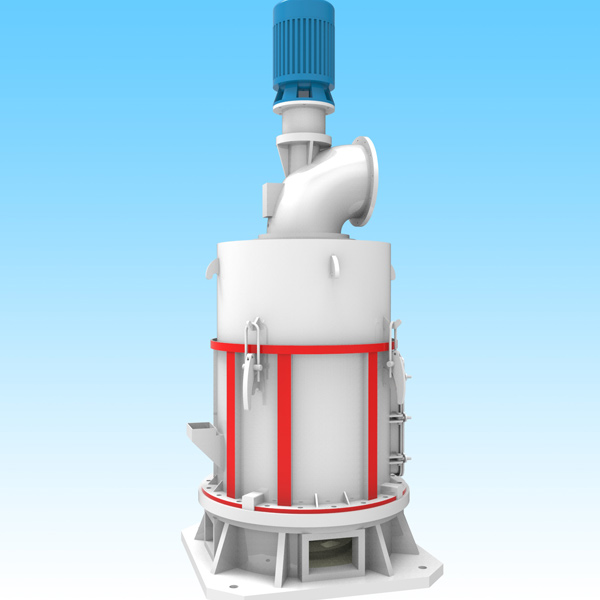

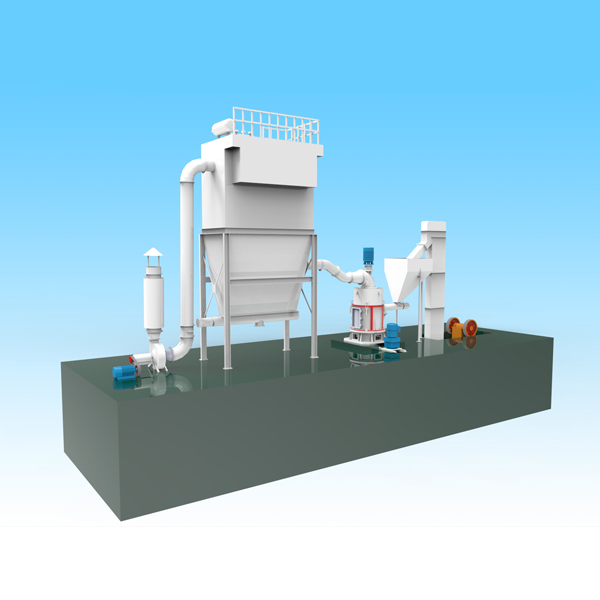

GKW1270 Micro Powder Mill is a new environmental superfine powder mill developed by our R&D team for grinding 400-1250 mesh powder. It is an enlarged type of GKW970. It is mainly used for grinding non-flammable and non-explosive materials, whose hardness below seven Moh’s hardness following humidity below 6%, such as dolomite, calcite, marble, barite, limestone, fuel ash etc.The high capacity, energy saving, and environmental features make GKW1270 mill become into an upgraded mill for ultrafine ring roller mill to grind 400-1250 mesh powder. It has been widely accepted and praised by more and more clients and experts in grinding mill industry. Under the policy of One Belt And One Road, it will go to all over the world on behalf of China.

GUIKUANG mill founded in1973, you are warmly welcomed to inquire freely.

Technical & Structural Benefits of GKW1270 Micro Powder Mill:

1. Finished particle size 400 mesh -1250 mesh (stepless adjustment);

2. Breakthrough hard materials and powdery materials, and grind the materials such as talc and fly ash;

3. Low cost of equipment wearing parts;

4. Convenient equipment maintenance, maintenance & replacement of wearing parts;

5. Low energy consumption and high output, for users to create better economic results;

6. Energy conservation and environmental protection.

|

Model

|

Max Feeding Size

|

Product Fineness

(mash)

|

Capacity

|

Total Installed Power

|

|

GKW970

|

≤10mm

|

400-1250mesh

|

500-3200kg/h

|

120kw

|

|

GKW1270

|

≤10mm

|

400-1250mesh

|

1000-6500kg/h

|

225kw

|

Electric Control Cabinet of GKW1270 Micro Powder Mill:

Electric control cabinet is assembled all electric control parts of the machine, carrying out concentrated controls.Check all electrical components in the cabinet before starting for looseness.

1. The motors of main machine and air blower adopt autotransformer device starting method.Time regulating relay KT can alternate the time.Check that the alternating time is 100s, otherwise, it is not allowed to start the machine.

2. Users must install variable frequency speed governor of turbine classifier on the face board of control cabinet depending on the position shown in the drawing.Only inserting the plug into the controller socket are required because the socket has already been connected.While classifier is working, close the air switch first, then regulate the frequency of speed governor, and make the classifier reach the required speed(that is to say, product attains required size).Before being shutdown, the knob of speed governor can be adjusted to the minimum position.Then turn off the air switch.

............