How to maintain the

ultrafine grinding mill machine when it fails, it is difficult for general operators to complete such a technical problem. The problem of mill failure is inevitable in the operation of equipment. Below, I will summarize 4 major maintenance techniques for reference, including four aspects: preventive maintenance, troubleshooting, production maintenance, and predictive maintenance.

First, preventive maintenance, make detailed plans for ultrafine grinding mill equipment operation, including production volume, rest time, professional maintenance department, etc. Reasonable work arrangements and preventive measures can extend the service life of equipment and parts and increase production efficiency.

1. Formulate a reasonable production plan to avoid overworked equipment.

2. Set up a special maintenance department, and then check regularly. If we find that the quality of finished products and production efficiency are not normal, we should eliminate them in time.

3. Lubricate or replace worn or worn parts of equipment.

Second, fault maintenance, which refers to the unplanned maintenance of

Raymond mill in case of failure or performance degradation. It is a kind of behavior of troubleshooting according to specific fault phenomenon, such as the problem of no powder coming out of the powder collector and abnormal dust at the feed inlet, etc. Such common failures are described in the detailed technical description of grinding equipment. In addition, the fault problem cannot be handled at will. The technician should be consulted or the technician should be informed of the troubleshooting. In addition, the whole process of troubleshooting should be carried out under the condition of power failure to avoid other accidents.

Third, production maintenance, which mainly refers to problems affecting production planning, there are two possible factors causing failure: one is the performance problem of the device itself, and the other is the problem of operator. Generally, there is no quality problem when testing the machine, so the quality of grinding equipment in the later stage of production is much less influential, which may be caused by the operator. For example, the poor sealing of the powder lock device will result in low or even no powder output and low output. The uneven feeding will affect the evenness of the finished products and cause problems such as blockage.

Fourth, predictive maintenance, which is similar to preventive maintenance but fundamentally different, prevention is the prevention of all possible problems, but the essence does not necessarily occur, and anticipation is the anticipation of what is about to happen, which has been predicted to varying degrees, but has not caused serious consequences. Based on the information provided by the status monitoring and diagnosis technology, necessary and appropriate maintenance can be carried out before the failure occurs. Most skilled operators can detect potential faults in advance through sound and finished products, so as to prevent and cure them early.

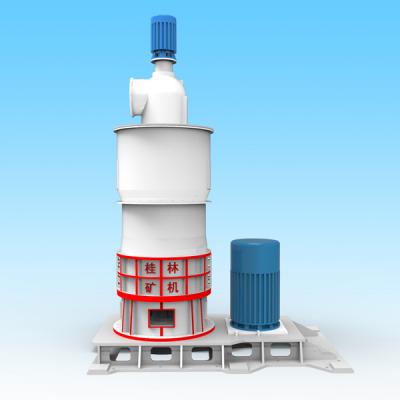

Ultrafine Mill2017/11/28GKH1032D Ultrafine Ring Roller Mill is a developed kind of grinding mill with optimized design & structure. It is mainly used in deep processing non-metallic mineral stones, hardness below seven ...

Ultrafine Mill2017/11/28GKH1032D Ultrafine Ring Roller Mill is a developed kind of grinding mill with optimized design & structure. It is mainly used in deep processing non-metallic mineral stones, hardness below seven ...