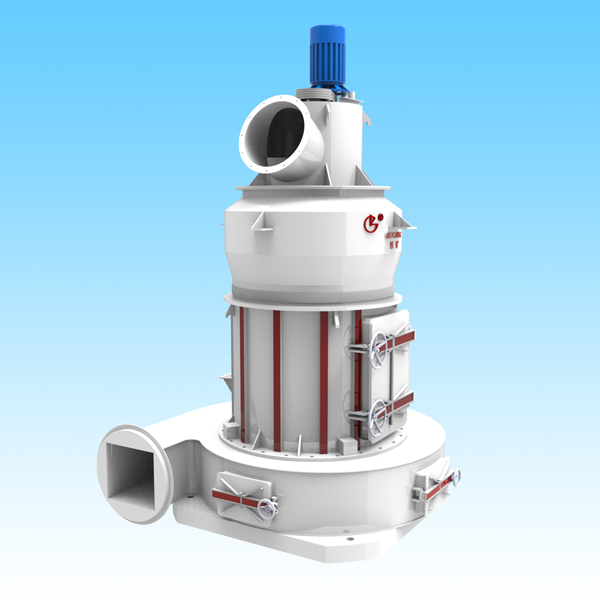

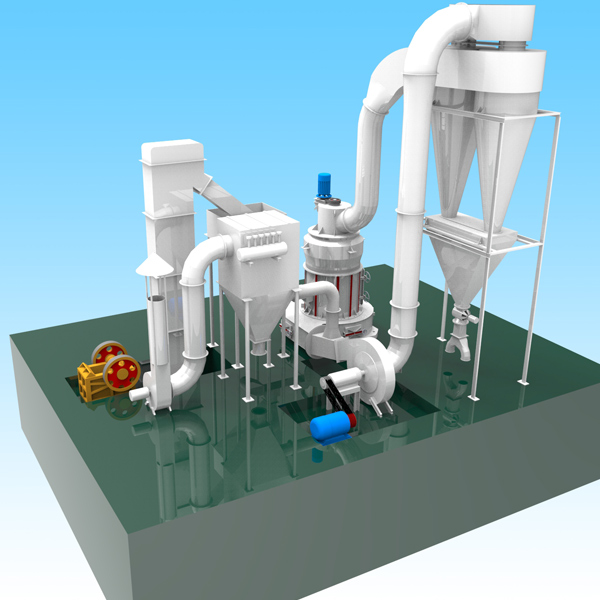

4R3220 Pendulum Grinding Mill is suitable for non-flammable and non-explosive materials, withhardness less than 7, with moisture less than 6%, such as, barite, limestone, ceramics, slag, gypsum, calci...

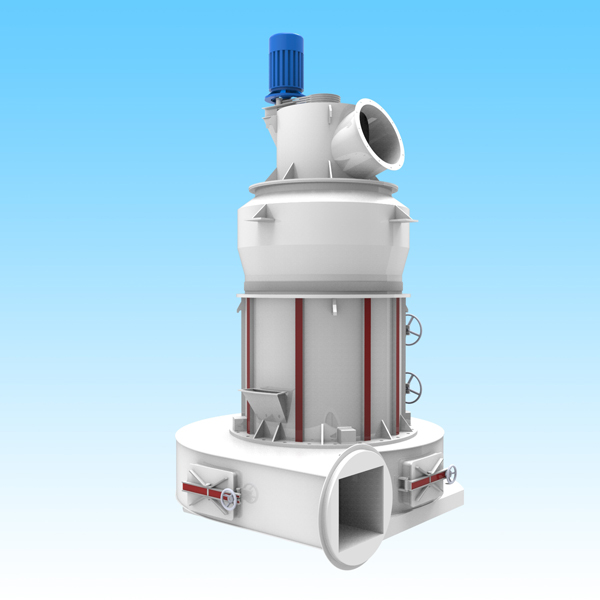

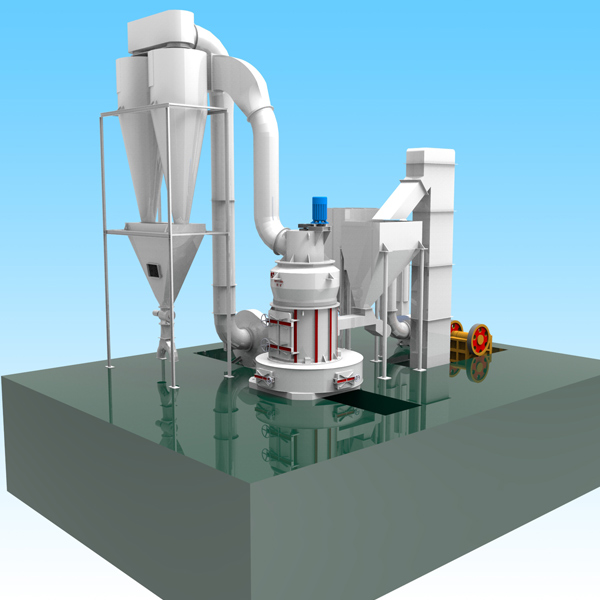

Technical & Structural Benefits of GK2500 Pendulum Grinding Mill:1.This model has high output, high efficiency and energy saving. It has small floor area and saves workshop.2.Large conveying capac...

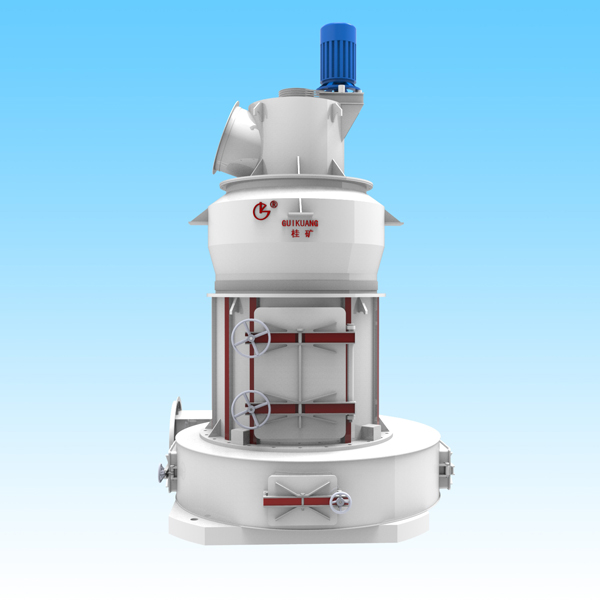

Technical & Structural Benefits of GK2150 Pendulum Grinding Mill:1.This model has high output, high efficiency and energy saving. It has small floor area and saves workshop.2.Innovative design of ...

|

Model |

Max Feeding Size |

Product Fineness |

Capacity |

Gross Weight |

Total Installed Power |

|

GK2500 |

≤35mm |

80-325mesh |

15000-50000kg/h |

66t |

625kw |

|

GK2150 |

≤35mm |

80-325mesh |

10000-40000kg/h |

64t |

548kw |

|

GK1720A |

≤35mm |

80-325mesh |

6000-25000kg/h |

49t |

424.5kw |

|

GK1620A |

≤30mm |

80-325mesh |

3000-18000kg/h |

34.5t |

329.5kw |

|

GK1500 |

≤20mm |

80-325mesh |

2500-16000kg/h |

31t |

242kw |

|

5R4128 |

≤20mm |

80-325mesh |

2000-14000kg/h |

28.5t |

220kw |

|

5R4125 |

≤20mm |

80-325mesh |

2000-14000kg/h |

28.5 |

202kw |

|

GK1280 |

≤20mm |

80-325mesh |

1500-10000kg/h |

19t |

133.5kw |

|

4R3220 |

≤20mm |

80-325mesh |

1000-7000kg/h |

14.6t |

101.5kw |

we will contact you within 24 hours.