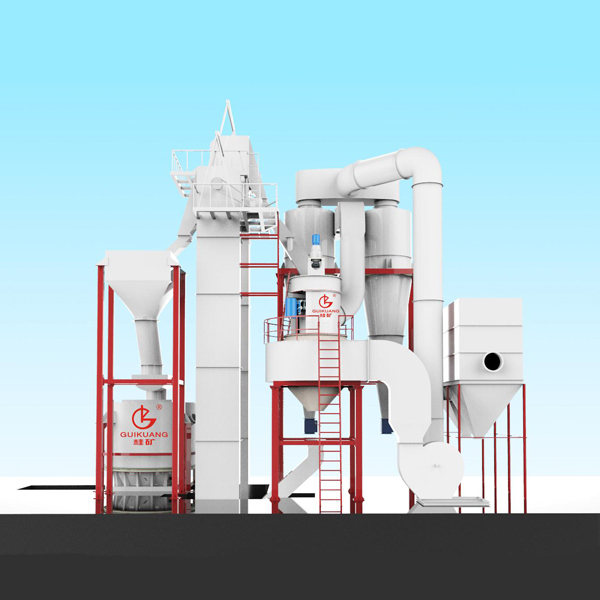

After years of research and experiment, we have designed the newest GKC series super-large energy-saving grinding mill with high efficiency. GKC grinding mill has secured patented technology. The unique design, outstanding performance and integrated with large scale, high efficiency and low energy consumption make it perfect to meet the trending demand of national industrial development and powder industry for the production and development of large-scale industrialization. GKC series large grinding mill has been widely used in various types of large-scale grinding production line project, such as metallurgy, mining, electricity, building materials, chemicals, refractory materials, etc. Buy large grinding mill directly from factory with competitive price.

GKC Series Energy-Saving Super-Large Grinding Mill Advantages:

Based on a high starting point, high standards, high efficiency, high yield, and setting professionalization and functionalization as integration, GKC Grinding Mill has an excellent performance advantage in the process of grinding:

-

Based on same installed power, the production capacity is higher 30%-60% than other grinding mills.

-

Based on same capacity, the price is much lower than vertical mills.

-

The equipment adopts the external classification system: the powder is directly graded from the top to the bottom, drastically reducing the energy consumption of the fan, and the unqualified product enters the collector without obstruction, and the classification efficiency is extremely high.

-

There is no strong air flow inside the mill, the material is not easy to suspend, the material is distributed evenly inside the mill, effectively reducing the mineral repetitive grinding. Therefore the grinding efficiency is highly improved.

-

360°omni-directional feeding material, the feeding efficiency is highly improved.

-

Due to the circular grinding system, the moisture of the material is fully volatilized during the grinding process, which means the material moisture less than 10% can be ground directly, no need drying equipment, significantly reducing procurement costs, production costs and pollution emissions.

-

GKC mill can produce coarse sand, which can remove the process procedure of hammer crusher. Reduce the dust pollution and noise brought by the hammer crusher.

-

The 10-100 mesh powder from reverting material can be the raw materials of real stone paint, wall painting, glass and so on. The secondary grading system can produce powder above 1000mesh and makes a great profit for the enterprise.

-

Stable running, small vibration, low noise; pulse dust collector with the high dust removing efficiency can meet the standard of national emissions.

-

Evenly feeding greatly reduces empty grinding to extend the mill service life and reduce the spare part cost.