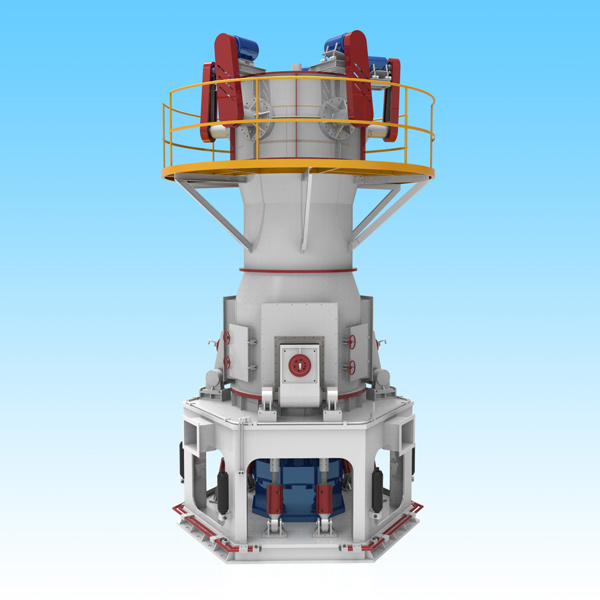

With more than 40 year studying and researching by engineers from Guilin Mining Machinery Co., LTD and introducing foreign advanced technology, GK series vertical grinding mill has been one advanced energy-efficient grinding equipment integrated with drying, grinding, grading and collecting.

GK vertical mill is with advantages of high grinding efficiency, low power consumption, big feeding size, product fineness easy to adjust, simple processing, small land occupation, low noise, small dust, easy maintenance, low operation cost, less wear-resistant materials. It is widely applied in cement, power, metallurgy, chemical, non-metallic minerals industry. It is mainly used for grinding cement raw materials, clinker, power plant desulfurization lime powder, slag powder, manganese, gypsum, coal, barite, calcite and other materials.

LM1100 Vertical Roller Mill Advantages:

1. High Energy-efficient

(1) High grinding efficiency, low energy consumption. Saving 40% -50% energy consumption

compared with the ball mill;

(2) High production capacity, can use off-peak electricity.

2. Convenient maintenance and low operating cost.

(1) The roller can be pulled out of the machine by the hydraulic device, which makes enough space for replacing liner convenient maintenance;

(2) The roller sleeve can be used upside down, extending the service life of wear-resistant materials;

(3) No need to place raw material on the grinding disc before starting the machine and the mill can be started without load, which avoids troublesome start-up;

(4) Low abrasion loss, the grinding roller, and grinding disc are made of special material, with long service life.

3. Low investment cost. Integrated with crushing, drying, grinding, conveying as a whole system. Simple processing, less equipment system, compact structure, small land occupation ( 50% of ball mill’s land occupation). The mill can be installed out-of-door. Construction cost is low, directly reduce enterprise investment cost.

4. Final product(powder) is stable

(1) The material has a short stay in the mill. It is easy to control the grain size distribution and chemical component, and the product quality is stable.

(2) Regular particle shape, narrow particle size distribution, good fluidity, and extensive adaptability

5. High reliability

(1) Rollers with height-controlled device, which avoids strong shaking caused by the short of material on the table;

(2) Newly-designed roller sealing device ensures reliable sealing without sealing the blower, which can reduce the oxygen content in the mill to prevent the possibility of explosion;

6. Environmentally friendly

(1) Lower vibration and noise;

(2) The whole system is overall sealed and operates under negative pressure, no powder overflow, the no-dust workshop can be realized.

(3)Vertical mill is the new technology equipment with lower power consumption which is advocated by the government. This will help to increase the enterprise competitiveness of powder industry in the local region even the whole country.

7. High Automatic Level

PLC automatic control system, remote control, easy operation and maintenance, lower labor cost.

|

Model

|

Max Feeding Size

|

Product Fineness

(mash)

|

Capacity

|

Total Installed Power

|

|

GKLM1100

|

≤10mm

|

325-1250mesh(Secondary grading 1250-3000)

|

1500-12000kg/h

|

250kw

|