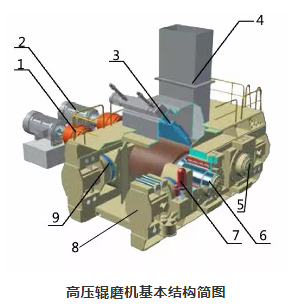

The structure of high pressure grinding roller mill

The structure of high pressure

grinding roller mill is various, but its principle is basically similar. The roller press is mainly composed of feeding device, material position control device, a pair of sticks, rotating device (motor, pulley, gear shaft), hydraulic system, and horizontal leakage prevention device.

Basic structure diagram of high pressure

grinding roller mill

1- drive system and torque balance device; 2 - the motor; 3- material layer adjustment device; 4 - hopper; 5- fixed roller system; 6- moving roller system; 7- energy accumulator; 8 - frame; 9- hydraulic cylinder;

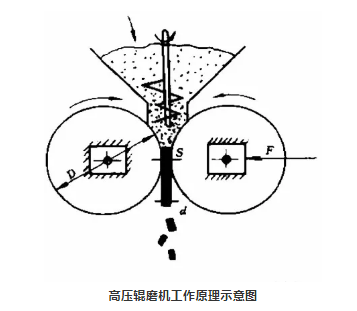

The working principle

The material enters into the pressure zone between two rollers rotating in phase, under the action of friction of roller pressure surface and gravity of material column. As the roll seam becomes smaller and smaller, the pressure on the material layer becomes greater and greater. Finally, the material is pressed into the material cake and falls down between the two rolls.

LM1250 Vertical Roller Mill2017/11/28

LM1250 Vertical Roller Mill2017/11/28 LM1100 Vertical Roller Mill2017/11/28With more than 40 year studying and researching by engineers from Guilin Mining Machinery Co., LTD and introducing foreign advanced technology, GK series vertical grinding mill has been one advanced e...

LM1100 Vertical Roller Mill2017/11/28With more than 40 year studying and researching by engineers from Guilin Mining Machinery Co., LTD and introducing foreign advanced technology, GK series vertical grinding mill has been one advanced e...