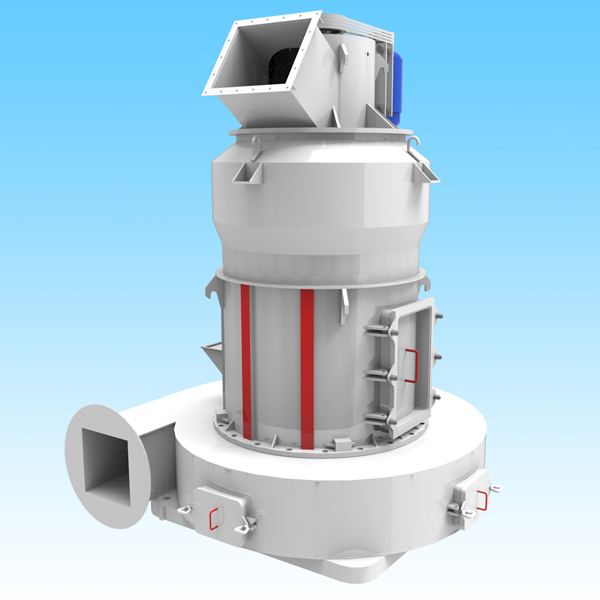

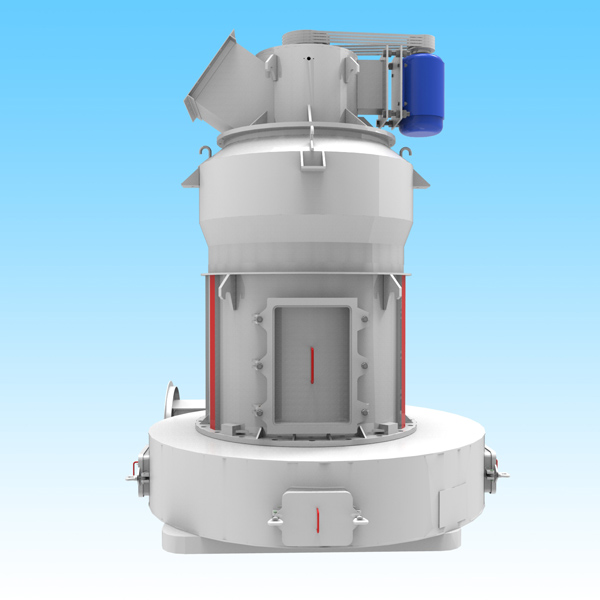

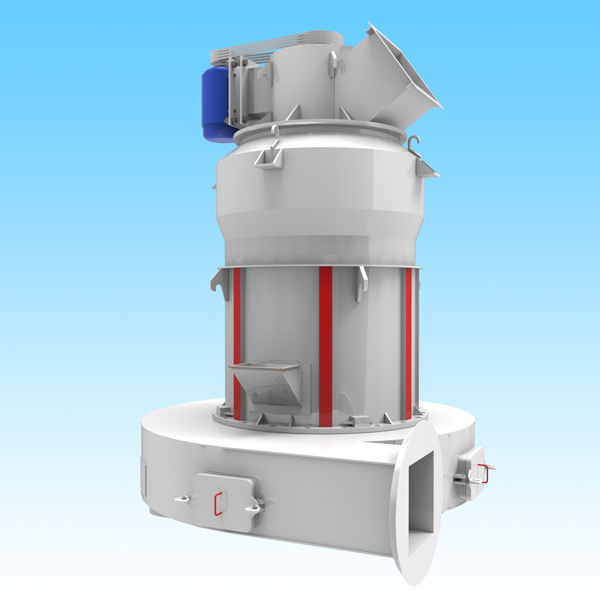

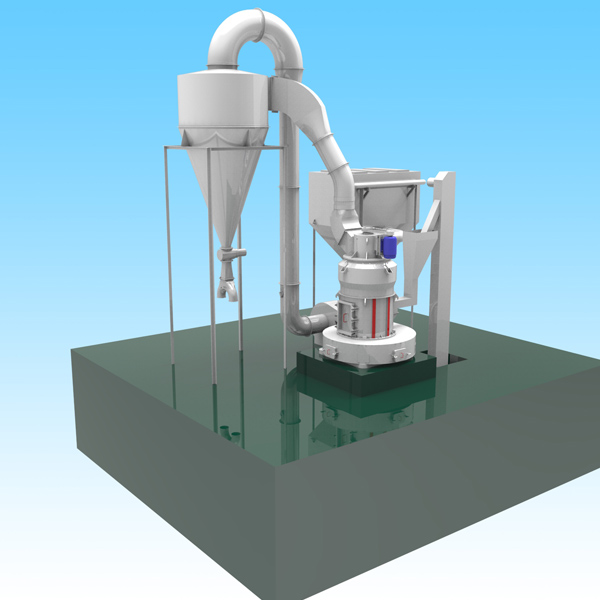

GK2500 Grinding Mill is designed by our technicians according to market development demand. This is a superlarge innovative type mill with optimized design.

This High Pressure Suspension Mill has high output, high-efficiency, and energy saving. It has small floor area and saves workshop.

Strong ability of shoveling material: Adoptingsuper large shovel blade to shovel material as much as possible to be ground into the space between the rollerer and ring.Expanding Grinding Space: The gr...

|

Model |

Max Feeding Size |

Product Fineness (mash) |

Capacity |

Gross Weight |

Total Installed Power |

|

GK2500 |

≤35mm |

80-325mesh |

15000-50000kg/h |

66t |

625kw |

|

GK2150 |

≤35mm |

80-325mesh |

10000-40000kg/h |

64t |

548kw |

|

GK1720A |

≤35mm |

80-325mesh |

6000-25000kg/h |

49t |

424.5kw |

|

GK1620A |

≤30mm |

80-325mesh |

3000-18000kg/h |

34.5t |

329.5kw |

|

GK1500 |

≤20mm |

80-325mesh |

2500-16000kg/h |

31t |

242kw |

|

5R4128 |

≤20mm |

80-325mesh |

2000-14000kg/h |

28.5t |

220kw |

|

5R4125 |

≤20mm |

80-325mesh |

2000-14000kg/h |

28.5 |

202kw |

|

GK1280 |

≤20mm |

80-325mesh |

1500-10000kg/h |

19t |

133.5kw |

|

4R3220 |

≤20mm |

80-325mesh |

1000-7000kg/h |

14.6t |

101.5k |

we will contact you within 24 hours.