When the

ultra-fine Raymond mill Machine works, the materials to be crushed are added into the machine from the feeding hopper on the side of the machine cover shell. It relies on a roller-grinding device suspended on the main frame to rotate around a vertical axis while rotating itself. Because of the action of centrifugal force during rotation, the grinding roller swings outwards and presses firmly on the grinding ring, so that the shovel picks up the material and sends it between the grinding roller and the grinding ring. As a result, the grinding roller can crush the material by rolling. The process of wind selection: after the material is grinded, the fan blows the wind into the main engine shell, blowing up the powder, sorting through the analyzer above the grinding room and passing the coarse material into the grinding room and regrinding. The fineness conforming to the specifications will enter the cyclone collector along with the wind flow, and after collection, it will be discharged through the powder outlet, that is, the finished product. The air flow is fed back into the fan by the return duct at the upper end of the cyclone collector. The increase of the air volume of the circulating air channel is partly discharged by the exhaust pipe between the fan and the main engine, and enters the small cyclone collector for purification.

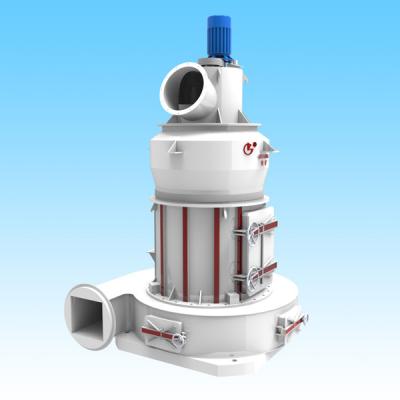

GK1500 Raymond Mill2017/11/28Optimized Structure & Innovative Design with 5 national patents.High output: With high grinding efficiency, the capacity will be increased by 20-40% than 5R4128 raymond mill.Main unit: unique buff...

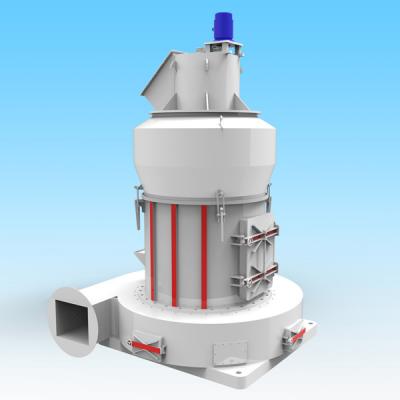

GK1500 Raymond Mill2017/11/28Optimized Structure & Innovative Design with 5 national patents.High output: With high grinding efficiency, the capacity will be increased by 20-40% than 5R4128 raymond mill.Main unit: unique buff... GK1620A Raymond Mill2017/11/28GK1620A Modified Grinding Mill, high output and low consumption, is specially designed by our technicians according to market development demand. This is medial type between 5R and 6R.High Output--Wit...

GK1620A Raymond Mill2017/11/28GK1620A Modified Grinding Mill, high output and low consumption, is specially designed by our technicians according to market development demand. This is medial type between 5R and 6R.High Output--Wit... GK1720A Raymond Mill2017/11/28GK1720A Grinding Mill is designed by our technicians based on GK1720 mill.This is a large type mill with optimized design.1、Optimized shock-absorption design for the main unit, reduce vibration when ...

GK1720A Raymond Mill2017/11/28GK1720A Grinding Mill is designed by our technicians based on GK1720 mill.This is a large type mill with optimized design.1、Optimized shock-absorption design for the main unit, reduce vibration when ...