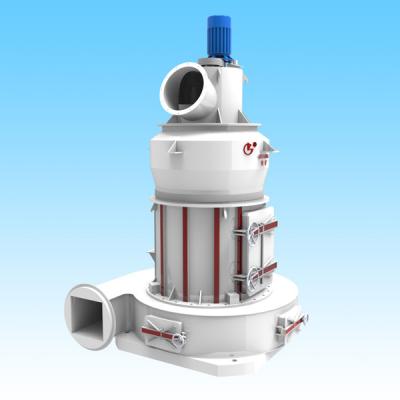

An overview of

ultrafine grinding mill

Its crushing range is quartz, feldspar, porcelain soil, clay, bentonite, calcite, talc, barite, fluorite, clay, gypsum and other non-inflammable and explosive mineral materials with a hardness of less than Mohs grade 7.

It is named according to the fineness of grinding materials and fineness of outgoing materials

Installation and maintenance of ultrafine mill:

The maintenance of the machine is a very important and regular work. It should be closely coordinated with the operation and maintenance of the machine.

Maintenance of ultrafine grinding mill components:

1. Bearing

The bearing of the crusher bears all the load of the machine, so good lubrication has a great relationship with the service life of the bearing. It directly affects the service life and operation rate of the machine.

Main oil filling place of this machine: (1) rotating bearing (2) roll bearing (3) all gears (4) movable bearing and sliding surface.

2. The newly installed hoop is easy to loosen and must be inspected frequently.

3. Pay attention to whether all parts of the machine are working normally.

4. Pay attention to check the wear degree of wearables, and replace worn parts at any time.

5. On the floor of the bottom shelf of the moving device, dust and other materials should be removed so as to prevent the machine from moving on the bottom shelf when it encounters materials that cannot be broken, resulting in serious accidents.

6. If the bearing oil temperature rises high, stop the vehicle immediately and check the reason to eliminate it.

7. If there is any impact sound during the operation of the rotating gear, it shall stop and check immediately and eliminate it

Installation test for ultrafine grinding mill:

1. The equipment shall be installed on a horizontal concrete foundation and fixed with anchor bolts.

2. During installation, attention should be paid to the vertical between the main body and the horizontal body.

3. After installation, check whether the bolts in all parts are loose and whether the main engine warehouse door is tightened. If so, please tighten it.

4. Power line and control switch are configured according to the power of the equipment.

5. After the inspection, carry out empty load test. If the test is normal, the production can be carried out.

GK1500 Raymond Mill2017/11/28Optimized Structure & Innovative Design with 5 national patents.High output: With high grinding efficiency, the capacity will be increased by 20-40% than 5R4128 raymond mill.Main unit: unique buff...

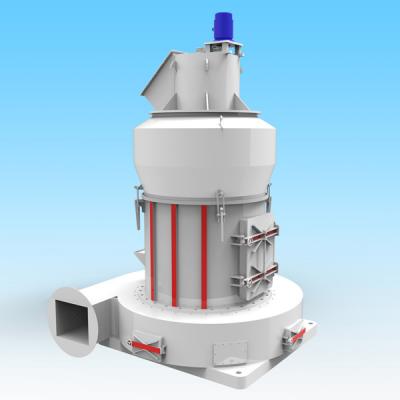

GK1500 Raymond Mill2017/11/28Optimized Structure & Innovative Design with 5 national patents.High output: With high grinding efficiency, the capacity will be increased by 20-40% than 5R4128 raymond mill.Main unit: unique buff... GK1620A Raymond Mill2017/11/28GK1620A Modified Grinding Mill, high output and low consumption, is specially designed by our technicians according to market development demand. This is medial type between 5R and 6R.High Output--Wit...

GK1620A Raymond Mill2017/11/28GK1620A Modified Grinding Mill, high output and low consumption, is specially designed by our technicians according to market development demand. This is medial type between 5R and 6R.High Output--Wit... GK1720A Raymond Mill2017/11/28GK1720A Grinding Mill is designed by our technicians based on GK1720 mill.This is a large type mill with optimized design.1、Optimized shock-absorption design for the main unit, reduce vibration when ...

GK1720A Raymond Mill2017/11/28GK1720A Grinding Mill is designed by our technicians based on GK1720 mill.This is a large type mill with optimized design.1、Optimized shock-absorption design for the main unit, reduce vibration when ...