Application of Ultrafine grinding mill

Ultrafine grinding mill is mainly applicable to the grinding of metallurgical, building materials, chemical, mining and other mineral materials. It can be used to grind feldspar, calcite, talc, barite and other mineral materials.

Ultrafine grinding mill is an important content in powder engineering, including ultrafine grinding of powder raw materials, high precision grading and changes in surface activity. According to the size or particle size of raw materials and finished products, crushing can be divided into

primary crushing, fine crushing, micro crushing and ultrafine grinding, which is a general classification. It is worth noting that the particle size of submicron powder varies from industry to industry in different countries due to its use, different preparation methods and different technical levels.

The submicron powder is generally non-sieve crusher. The particle size of crushing materials is controlled by airflow speed. The particle size of crushing materials requires 95% to pass 0.15mm. It is generally used for special aquatic bait or open aquatic feed.

Features of Ultrafine grinding mill

1. Increase the area of non-controlled particle size in the crushing cavity;

2. The parallel zone changes the structure of the crushing cavity, and the parallel zone is short and the Angle is flat.

3. The crushing ratio is large, and the product is fine and even, reducing the load of

grinding equipment.

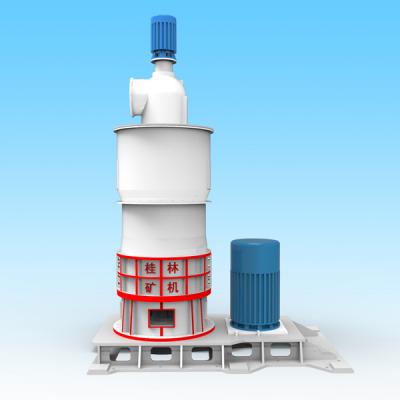

Ultrafine Mill2017/11/28GKH1032D Ultrafine Ring Roller Mill is a developed kind of grinding mill with optimized design & structure. It is mainly used in deep processing non-metallic mineral stones, hardness below seven ...

Ultrafine Mill2017/11/28GKH1032D Ultrafine Ring Roller Mill is a developed kind of grinding mill with optimized design & structure. It is mainly used in deep processing non-metallic mineral stones, hardness below seven ...