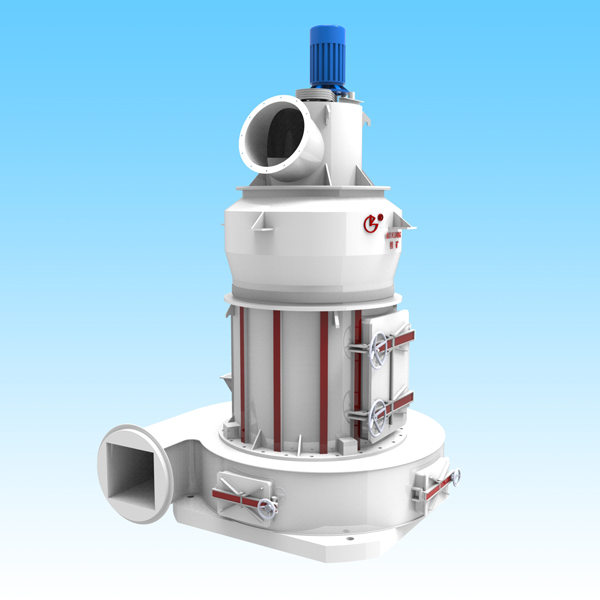

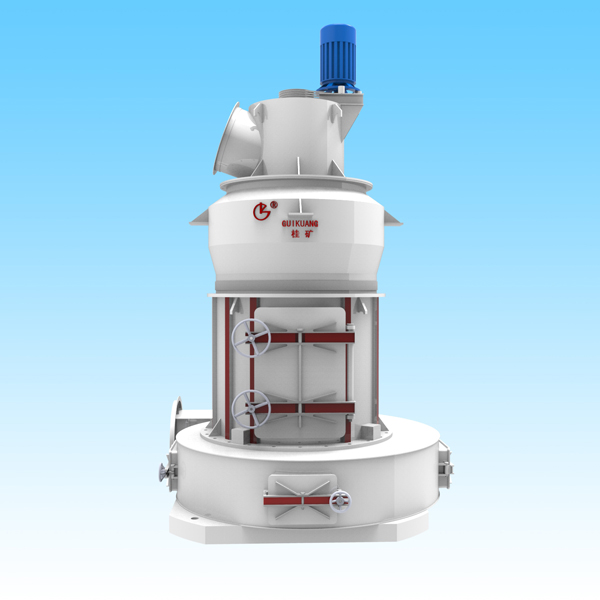

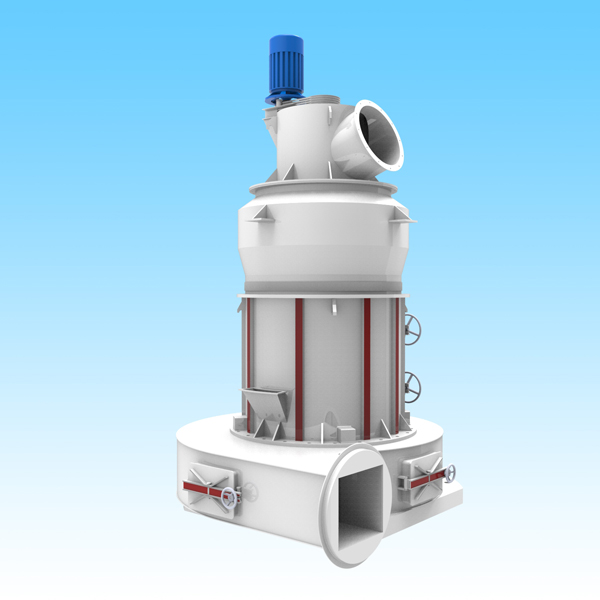

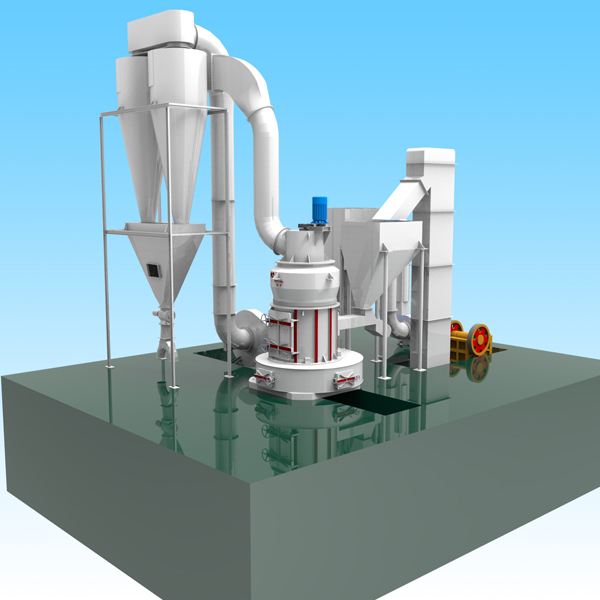

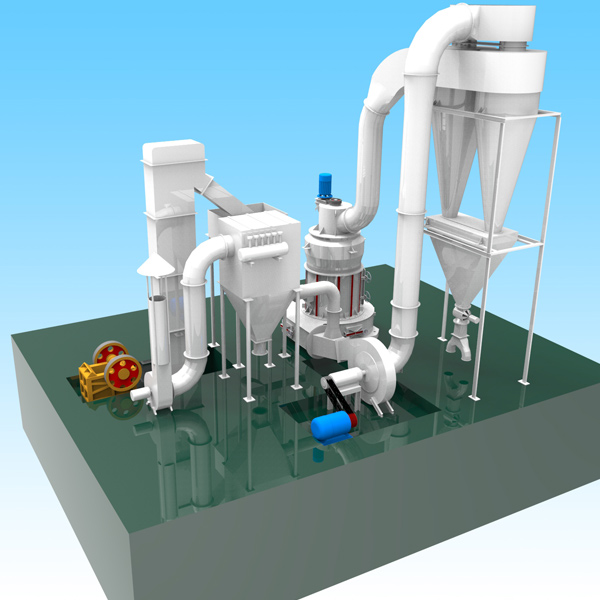

Technical & Structural Benefits of GK1500 Pendulum Grinding Mill

-

Optimized Structure & Innovative Design with 5 national patents.

-

High output: With high grinding efficiency, the capacity will be increased by 20-40% than 5R4128 Raymond mill.

-

Main unit: unique buffering structure for grinding roll assembly; the particular permanent non-wearing function for central shaft structure device.

-

Unique design for host structure: achieving no impact vibration before feeding material

-

Blower: adopting integrated high-pressure centrifugal blower, larger transmission capacity, optimized design for air volume and air pressure parameters, greatly improving the pneumatic conveying capacity.

-

Automatic control for air blower valve.

-

Parallel double cyclone collector: higher collection efficiency.

-

higher reliability, lower vibration, energy saving and environmental protection.

-

Intelligent electric control--PLC (optional).

|

Model

|

Max Feeding Size

|

Product Fineness

(mash)

|

Capacity

|

Gross Weight

|

Total Installed Power

|

|

GK2500

|

≤35mm

|

80-325mesh

|

15000-50000kg/h

|

66t

|

625kw

|

|

GK2150

|

≤35mm

|

80-325mesh

|

10000-40000kg/h

|

64t

|

548kw

|

|

GK1720A

|

≤35mm

|

80-325mesh

|

6000-25000kg/h

|

49t

|

424.5kw

|

|

GK1620A

|

≤30mm

|

80-325mesh

|

3000-18000kg/h

|

34.5t

|

329.5kw

|

|

GK1500

|

≤20mm

|

80-325mesh

|

2500-16000kg/h

|

31t

|

242kw

|

|

5R4128

|

≤20mm

|

80-325mesh

|

2000-14000kg/h

|

28.5t

|

220kw

|

|

5R4125

|

≤20mm

|

80-325mesh

|

2000-14000kg/h

|

28.5

|

202kw

|

|

GK1280

|

≤20mm

|

80-325mesh

|

1500-10000kg/h

|

19t

|

133.5kw

|

|

4R3220

|

≤20mm

|

80-325mesh

|

1000-7000kg/h

|

14.6t

|

101.5kw

|

Debugging of GK1500 Pendulum Grinding Mill:

1. Put transfer switch on the "manual" position.Start vibration feeder and increase gradually feeding electric current by adjusting silicon controlled feeding electric current. Along with the feeding electric current increases, the main engine electric current will increase accordingly and air blower electric current decreases gradually. The following conditions can judge host reach saturation:

a.When blast volume of air blower has a surplus, the rated electric current of the main engine will be the critical point to adjust. When feeding electric current increases to the rated electric current of main engine electric current, production capacity reaches the maximum. After two minutes put the transfer switch on "automatic" position.

Adjust intelligent electric current relay:Firstly twist rotary knob on the panel to left(maximum side) till on the position of two-thirds, then adjust tuning knob.Rotate it left and right till red light and green light flash in transformation,which is the maximum saturation point.

b.When blast volume of air blower is insufficient, that host is jammed will

be taken as the critical point to adjust.Main engine electric current increases along with the feeding electric current, while air blower electric current decreases gradually ,which Will come to a constant electric current to a certain extant.By this time it is a critical point of air blower jamming, the blower electric current will decreases apparently if increase feeding material.This point is the maximum production capacity of the host. After two minutes put the transfer switch on "automatic" position.Adjust intelligent electric current relay:Firstly twist rotary knob on the panel to left(maximum side) till on the position of two-thirds, then adjust tuning knob.Rotate it left and right till red light and green light flash in transformation,which is a maximum saturation point.

Mark host electric current value when any machine is jammed during adjustment.On next adjustment, the critical point should be lower than this value.

2. Adjust valve of after windpipe to make sure that dust does not escape from the feed opening of mainframe and that a small volume of air is absorbed.